SMC ニュース

Delivery of 13.2k TEU container at SHI

SMC is pleased to announce the Delivery ceremony completion of 13,200 TEU container vessel, Hull No. SN 2443 (mv “WAN HAI A10 – 明春”) at Samsung Heavy Industries Shipyard, Korea. This is the 4th vessel in a series of 13 x 13,200 TEU vessels ordered by Wah Hai Lines, Taipei.

The vessel was classed by ABS and built to Singapore flag requirements.

SMC Secures Plan Approval and Site Supervision Services with NEOLINE for Its Sail Powered Ro-Ro Project

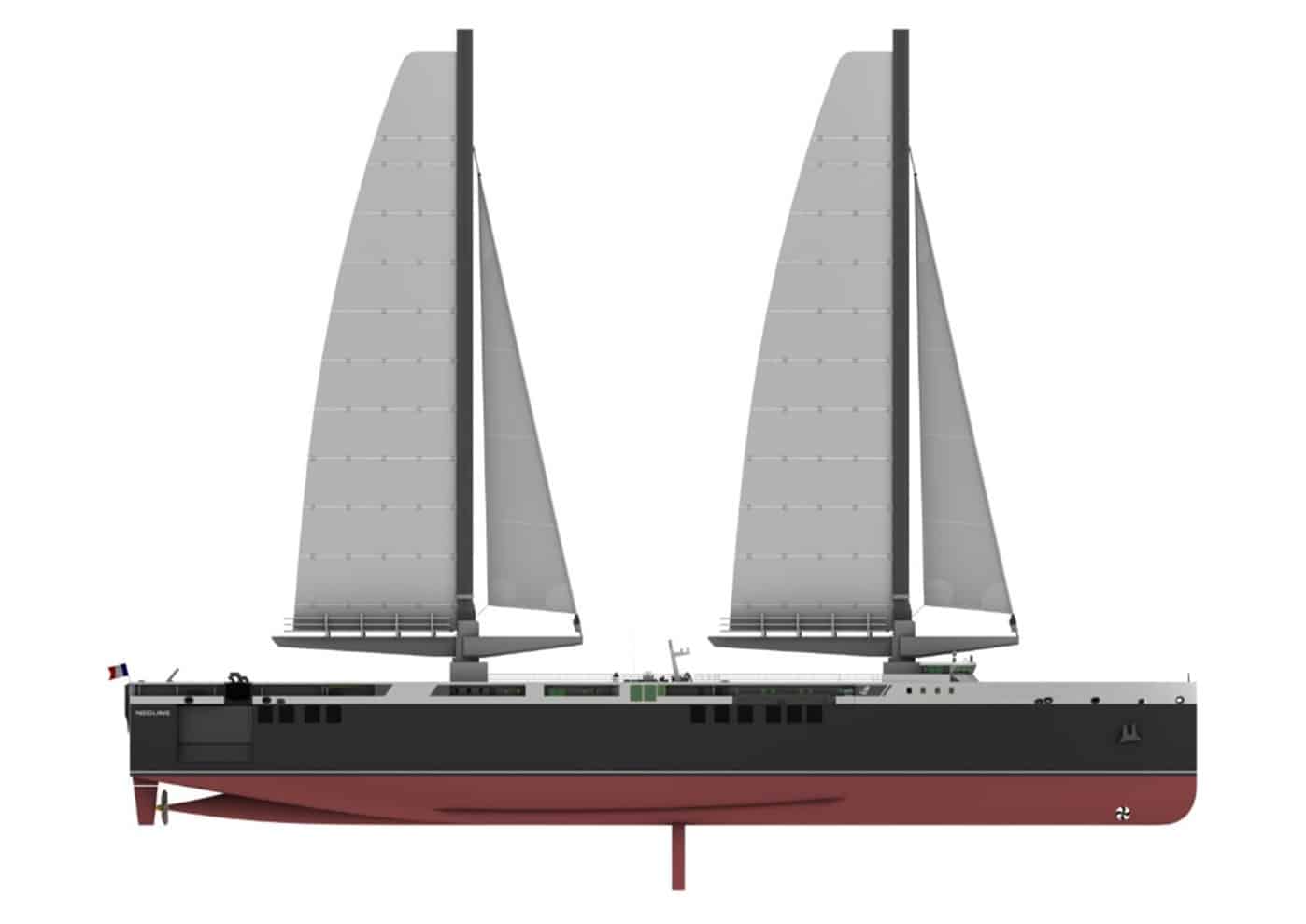

SMC is pleased to announce the signing of agreement with NEOLINE, France to provide plan approval and site supervision services for 1 x 136 m Sail Powered Ro-Ro – Neoliner, which will be constructed in RMK MARINE shipyard, Türkiye.

Neoliner (credit: Neoline/MAURIC)

Rendering Video of Neoliner (credit: Neoline/MAURIC)

The plan approval began immediately following the signing of the agreement. The vessel’s construction is scheduled to start from November 2023 until June 2025, with S.M.C.’s site team of four supervisors in attendance.

The vessel, whose budget is more than 60 million euros, is one of the most significant initiatives in accelerating the decarbonization of the maritime sector. The 136-meter-long Neoliner, which boasts two 76-meter-high SolidSail folding carbon masts and retractable anti-drift plans, will be mainly propelled by its 3,000 sqm sail area. The Neoliner will be the first one equipped with a SolidSail rigging system, supplied by Chantiers de l’Atlantique. Its loading capacity will be 1,130 lane meters (2.8 m wide), 265 TEU, for a maximum weight of 5,000 tons of goods. Jean Zanuttini, CEO of NEOLINE calling it the first achievement of a more than 10-year project (Source: https://www.neoline.eu/en/neoliner-under-construction/).

Neoliner 136m with Solidsail (credit: Neoline/MAURIC)

Neoliner 136m with Solidsail (credit: Neoline/MAURIC)

Based in France, NEOLINE was driven and founded with the conviction that the working sail is the only truly sober, immediately available and powerful enough solution to propel cargo ships. NEOLINE aims to build sustainable shipping by offering maritime transport solutions that combine operational relevance and energy sobriety and moving towards zero emission transport (Source: https://www.neoline.eu/en/who-are-we/#historique).

SMC is very honored to have the opportunity to participate in this novel green project and make contribution towards decarbonization and changing the world for better.

Currently, SMC has six projects running at four shipyards in Türkiye, which has risen as an important shipbuilding market specialized in small and medium sized high value and technologically advanced vessels.

Note: The photos and the video in this article are sourced from: https://www.neoline.eu

Delivery of World’s Largest Double-Ended Hybrid Ro-Ro Ferry

After the successful delivery of SMC’s first LNG-fueled passenger vessels with the newbuilding project for TT-Line, the 28th of February 2023 marked another first for SMC — with the delivery of the world’s largest double-ended ferry to P&O Ferries. The P&O Pioneer, the first of the two ferries, was built and delivered at Guangzhou Shipyard International (GSI) China, departing from GSI on the 3rd of March bound for Singapore on its voyage to the UK.

P&O Pioneer

P&O Pioneer

P&O ordered the Pioneer and her sister ship Liberte at GSI in 2019, due for delivery later this year. SMC has been honoured to be involved in this futuristic green project throughout the whole process by providing technical consultancy, plan approval and construction supervision for these vessels. The two vessels lead the industry for the size, the hybrid power capabilities, and the luxury. They will operate between Dover (south coast of England) and Calais (northern France).

“P&O Pioneer” is the largest double ended ferry

With a gross tonnage of 47,394 and 230 meters in overall length, the two vessels are the largest double ended ferries of their kind. The new ferry will increase the number of passengers and vehicles in a single crossing as well as a substantial increase in efficiency due to size and speed. Its unique double-ended design will also make the turnaround in port faster and more efficient.

P&O Pioneer is the world’s first green vessel outfitted with two 75,00kw Azipods at each end, combined with the regulatory separated engine spaces, diesel electric generation, as well as battery storage and full electric propulsion. This unique combination allows the ships to operate at a speed of over 22 knots and a service speed of 20.8 knots. The large-capacity batteries outfitted allows the vessel a maximum storage capacity of 8.8 megawatts. Its capability to use the shore power and recharge batteries respectively at shore or underway provides consistent power supply and energy optimization.

The vessel boasts high level of automation. There are over 12,000 alarm points built into the various systems, and all controlled from one engine control room and two wheelhouses. The vessel can switch between one wheelhouse operation to the other with two simple change over switches (one on each wheelhouse); it can also instantly switch between diesel and batteries propulsion at the push of a single button.

Our (SMC) electrical and mechanical teams (plan approval experts as well as supervisors) had their work cut out for them since whilst the basics are well known, a lot of the design had never been used before and certainly not on this scale. It was a great sense of achievement for the suppliers, yard, class, owners and SMC when the sea trials were completed, and the test concluded satisfactory.

SMC Site Team and Owner Representatives @ GSI for POF Project

SMC Site Team and Owner Representatives @ P&O Pioneer Delivery Ceremony

There are more than 9,300 square meters of space with a certified capacity of 1,500 passengers in the vessels. Restaurants, bars, a gym, a children’s area, pet’s area, duty free shops, as well as other areas for entertainment and relaxation are all included in the vessel. Passengers can have a 180-degree view at each side of the vessel. The double ended ferry has three decks for vehicles, the top deck taking cars only and the other two decks taking trucks and cars. There is a double level drive on drive off facilities (deck 3 and deck 5) at both ends, again increasing the efficiency of the vessel and reducing the turnaround time in port. The car and truck decks are fitted with charge ports for the electric driven vehicles.

Our Hull supervisors and our Accommodation Outfitting supervisors were able to use our recent experience from other projects and comparing the required standards as well as those on offer from a different outfitting supplier we again managed to deliver a high-quality interior pleasing the owners’ seniors and the owners on site team.

SMC Site Team and Owner Representatives @ GSI for POF Project

“As the TT-Line vessels (delivered last year) were state of the art vessels and they are, working on longer routes and differing ports, the POF ferries will be the latest in their class and again with modern technologies working on a fixed short route will, I am sure, be the types of vessels to lead the ferries into the next century.” says Steve Nolan, who managed the TT-Line project and greatly involved with the POF project as Technical Director of SMC.

P&O Pioneer – Hotel Interior

Delivery of 2,600 TEU container at NYZ

SMC is pleased to announce Delivery of 2,600 TEU container vessel, Hull No. N2673 (mv ”SITC SHENGMING” – “海丰盛明”) at New Yangzi Shipbuilding, China. This is the 8th vessel in a series of 10 x 2,600 TEU vessels ordered by SITC Shipping Management Co., Ltd., China.

The vessel is classed by NK and built to Hong Kong flag requirements.

Steel Cutting of 2,400 TEU container at YZJ

SMC is pleased to announce Steel Cutting of 2,400 TEU container vessel, Hull No. YZJ2015-2225 at Yangzijiang Shipyard, China. This is the 2nd vessel in a series of 2 x 2,400 TEU vessels ordered by C.U. Lines Limited, China.

The vessel will be classed by LR and built to Singapore flag requirements, scheduled to be delivered on 31st January 2024.

Steel Cutting of 63.5k DWT at CXS

SMC is pleased to announce Steel Cutting of 63,500 DWT bulk carrier, Hull No. CX0669 at Chengxi Shipbuilding, China. This is the third vessel in a series of eight vessels ordered by Huaxia Financial Leasing Co., Ltd., China.

The vessel will be classed by ABS and built to the flag of Republic of the Marshall Islands, scheduled to be delivered on 2nd February 2024.

Steel Cutting of 37k bulk carrier at DSIC

SMC is pleased to announce the Steel Cutting of 37,000 DWT lake max dry cargo, Hull No. BC37K-2 at DSIC Shanhaiguan Shipbuilding Industry Co., China. This is the second vessel in a series of eight vessels ordered by Polsteam, Poland.

The vessel will be classed by LR and built to Malta flag requirements, scheduled to be delivered on 04th March 2024.

Keel Laying of 7,000 TEU container at SWS

SMC is pleased to announce Keel Laying of 7,000 TEU container vessels, Hull No. H1555 and H1556 at Shanghai Waigaoqiao Shipbuilding, China. This is the 6th and 7th vessels in a series of 12 x 7,000 TEU vessels ordered by Sea Consortium Pte. Ltd., Singapore. The vessels will be classed by ABS and built to Singapore flag requirements scheduled to be delivered on 22nd September 2023 and 27th September 2023 respectively.

Launching of 7,000 TEU containers at SWS

SMC is pleased to announce the Launching of 7,000 TEU container vessels, Hull No. H1550 and H1551 at Shanghai Waigaoqiao Shipbuilding Co. Ltd, China. This is the 1st and 2nd vessels in a series of 12 x 7,000 TEU vessels ordered by Sea Consortium Pte. Ltd., Singapore.

The vessels will be classed by ABS and built to Liberian flag requirements for H1550 and Singapore flag requirements for H1551, scheduled to be delivered on 21st June 2023 and 23rd June 2023 respectively.

Steel Cutting of 63.6k bulk carrier at COSCO Zhoushan

SMC is pleased to announce the Steel Cutting of 63,600 DWT bulk carrier, Hull No. N1140 at COSCO Zhoushan Shipyard, China. This is the first vessel in a series of three vessels ordered by Hongkong Zhoushan Yihai Shipping Co., Ltd, China.

The vessel will be classed by CCS and built to Liberia flag requirements, scheduled to be delivered on 31st January 2024.